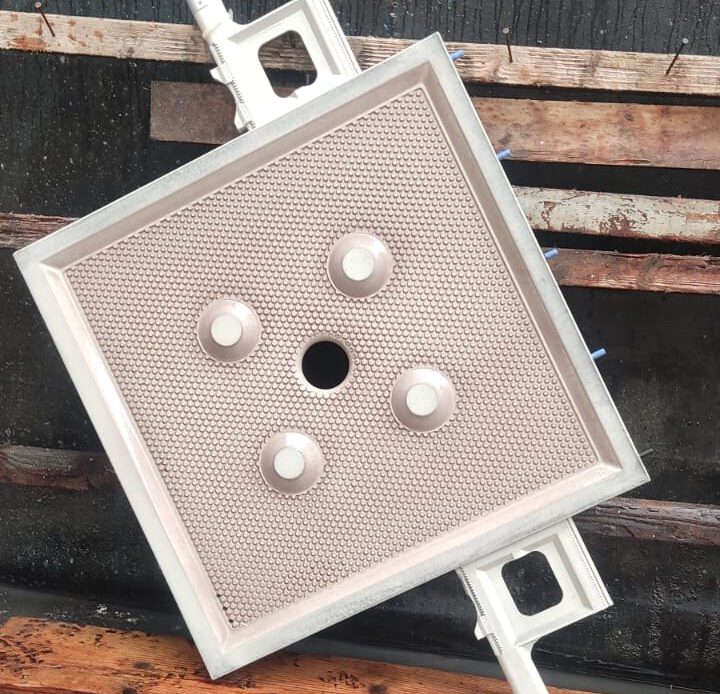

CENTRIFUGAL PLATES – ULTRASOUND

Cleaning of centrifuge dishes to give them the maintenance they deserve and that they perform their function without setbacks, extending their useful life and reducing factory breakdowns. BEFORE AFTER